Sourcing Smart: Choosing Materials That Work

Designing a modular glamping pod that’s easy to assemble, affordable, and built to withstand the UK climate requires more than just creativity — it demands smart material choices and careful detailing. At Snap Pod, we’ve spent months researching, testing, and designing around materials that not only look great but also perform reliably year after year.

Here’s a look at the key material choices and systems we’ve developed to bring Snap Pod to life — from curved glulam beams to waterproof sealants and modular SIPs.

🪵 Curved Glulam Beams: Structural Strength Meets Visual Appeal

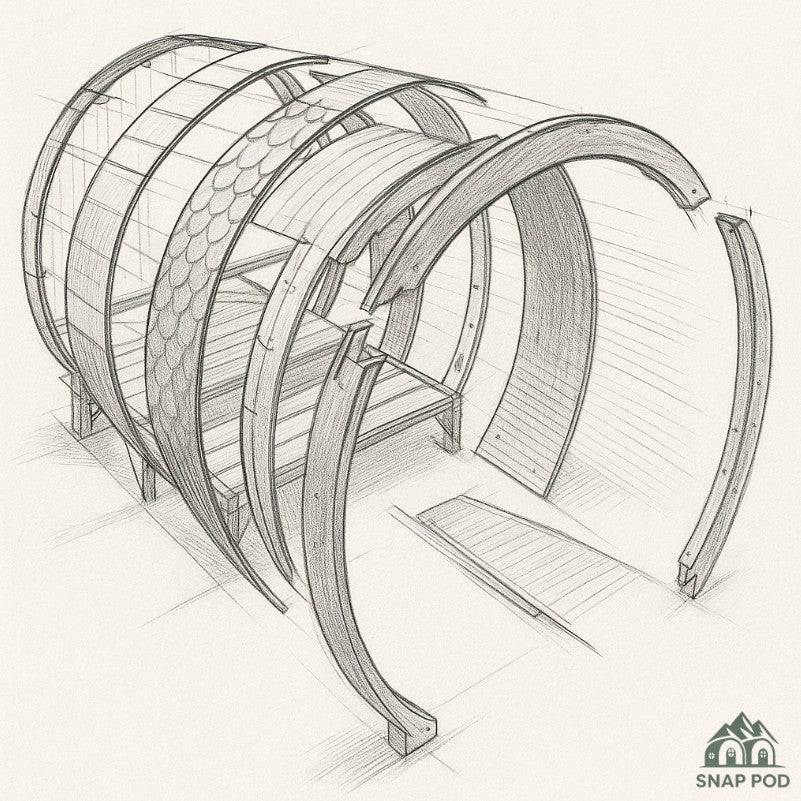

At the heart of Snap Pod’s modular design are the curved glulam beams that separate each pod section. These aren’t just aesthetic — they’re structural.

- Why Glulam? Glued laminated timber (glulam) allows us to create consistent, curved structural components that are stronger and more dimensionally stable than solid timber.

- In-House Production: For the prototype, we’re building the glulam beams ourselves. Once we have perfected the dimensions, we'll get them mass produced

- Joint Design: Each beam is made in three segments to fit on a pallet. The joints use a scarf joint reinforced by external steel flitch plates, bolted together for structural strength during transport and assembly.

🧱 SIP Panels: Fast, Insulated, and Panelised

To speed up construction and maximise energy efficiency, the pod sections are made from Structural Insulated Panels (SIPs). These pre-insulated panels are sandwiched between timber sheets, offering excellent thermal performance and structural stability.

- Insulation Standards: While Snap Pods are not classed as permanent dwellings, we’re designing to approach UK Building Regs thermal targets — typically aiming for U-values of 0.30 W/m²K or better for walls and roofs, exceeding what is legally required simply because we want to create a high quality product

- Curved SIPs: We’ve contacted UK manufacturers to explore curved SIP solutions or the option to pre-cut flat panels to fit the pod’s circular profile. These panels sit snugly between the glulam beams and form the structural skin of each module.

🔗 Section Connection: Waterproof, Modular & Strong

Since Snap Pods are built from modular 1.2m-long segments, they need to connect securely and stay watertight.

- Beam-to-Beam Connection: We use stainless steel U-brackets or custom Z-plates to lock curved beams together. These are manually clamped using bolts, allowing rapid on-site assembly with no specialist tools.

- Waterproof Sealing: To prevent ingress between sections, we embed a hydrophilic rubber gasket in a groove along each beam face. When the modules are clamped, the gasket compresses to form a seal — and if exposed to water, it expands to further block moisture.

🌧 Exterior Protection: Designed for UK Conditions

Snap Pods are built for real-world exposure — rain, wind, sun, and frost. That’s why we’ve paid special attention to finishes and durability:

- Protective Coating: All exterior-facing timber (especially the glulam beam ends) is treated with a 2-part exterior-grade polyurethane resin varnish. This seals the grain and provides excellent resistance to water, UV and fungal attack.

- Cladding Options: We’re exploring both thermally modified timber and black-painted larch or cedar for the exterior cladding — all selected for longevity and low maintenance.

- Roofing Membrane: A breathable but waterproof membrane sits over the SIP roof panel, ready for a curved outer cladding (e.g., timber slats or corrugated steel).

🔇 Thermal & Acoustic Comfort

We’re not just building shelters — we’re building sanctuaries. That means great thermal and acoustic performance, even with minimal services.

- Natural Insulation Materials: Alongside PIR core SIPs, we’re testing natural options like sheep wool or wood fibre batts for use in customisable modules.

- Ventilation Ready: Roof modules will feature pre-cut openings for vents to allow the free circulation of air and prevent damp.

📦 Modular Thinking = Smarter Logistics

Each Snap Pod module is designed to fit on a large standard UK pallet (1.2m x 2.4m).

This approach lets us:

- Deliver flat-packed to tight rural sites

- Minimise shipping costs

- Enable rapid unload and setup — no crane needed

The Bigger Picture

Every choice we've made — from pine laminations to SIPs, from gaskets to glues — reflects the Snap Pod philosophy:

- Make it modular

- Make it beautiful

- Make it last

We’re not just designing pods. We’re building a system that empowers others to live closer to nature, without the complexity of traditional construction.

Follow the Snap Pod Journal for more deep dives as we continue to prototype, test, and refine the build.